Everything to Know About Hydraulic Press Machines (Size, Price, Uses)

Hydraulic press machines are common in workshops and factories, and they offer a lot of great uses in many industries. If you’re looking to buy one, it helps to be familiar with ideal usage, pricing, the different types, and how they’re powered, among other things. This way, you can make an informed buying decision.

A hydraulic press machine uses compressed fluid in cylinders to create the force required to move, bind, or press objects together. There are many different types, each with different pricing, size, weight, and intended use.

The rest of this article will explain everything you need to know about hydraulic presses, including their history, the different types, how they work, pricing, benefits, what they’re commonly used for, and so much more. It’ll also cover how to design one from scratch, so be sure to stick around for that interesting bit. Let’s dive in!

Hydraulic Press History

The field of hydraulics, which is the technology that uses the flow and control of fluids, has been around for thousands of years. However, no one created a machine specializing in hydraulic technology until the late eighteenth century.

DESIGN NEW DXF FILES ONLINE IN MINUTES

OUR NEW FAST ONLINE GIZMO-DESIGN DXF PLATFORM COMING SOON

- Customize Artwork & Other DXF FILES Online Fast

- Personalize Them

- Download Your Files & Cut

Take A 30 Second Survey – Receive Free Fire Pit Files and Get On The VIP Waiting List To Try For Free!

The hydraulic press was created in 1795 by Joseph Bramah, an English inventor and locksmith who lived from April 1748 to December 1814. In addition to the hydraulic press, Bramah invented a pick-proof lock, which took sixty-seven years before someone could open it. Bramah’s other inventions include a water closet, a wood planing machine, and a banknote numbering device.

The first hydraulic press used a basic cylinder to create the force needed to press objects, and it was similar to the ones used today in design. However, the hydraulic presses that are used today are of much higher quality. And you can find different types of hydraulic presses available that are suitable for different materials, jobs, and workspaces. The next section will explain the science behind hydraulic presses and how they work.

How Does a Hydraulic Press Work?

A hydraulic press works by compressing fluid between two interconnected cylinders (the plunger and the ram) to generate force. During a press, a modest amount of force is applied to the plunger, pressing hydraulic fluid towards the ram. The fluid then raises the ram piston with greater force.

In simpler terms, the force applied to the plunger’s piston is evenly transmitted to the ram’s piston. Although, when it reaches the ram’s piston, it’s magnified. This “magnification” is precisely why you can crush an object with a fraction of the force you’d typically need. It happens due to the size difference between the cylinders (the ram is always larger), and Pascal’s principle.

There is actually a lot that goes into the question “how does a hydraulic press work”. So much so that I made an entire article about it. So if you want to learn more than the bare-bone basics, check out the article here. It covers all of the physics behind hydraulic presses, along with how to properly use one.

LEARN MORE ABOUT HOW A HYDRAULIC PRESS WORKS

What Is a Hydraulic Press Used For?

Hydraulic presses are used to bind items together, bend/straighten metal parts, or hold materials as they’re being worked on. These machines are most commonly used in factories and manufacturing plants due to the speed and precision with which they shape and create objects on a large scale.

Here are some of the most common industries that use hydraulic presses:

- Automotive

- Aerospace

- Construction and architecture

- Home appliances and tools

- Ceramics

- Concrete

- Military vehicles

- Scrap baling

- Powder compacting

All of these industries use hydraulic presses in unique ways. Most are creating something new, and the hydraulic press helps with either a small part of the project (like one piece or holding items together), or a significant portion of the job (like when building a car).

Presses for Farms and DIYers

Farms also use hydraulic presses when working with bearings and gears. The hydraulic presses used in farms are usually smaller than those used in larger factories, but they also get used less often, in applications that don’t require as much force.

Even individuals who do not work on a farm or run another kind of small business can benefit from a hydraulic press. Essentially, anyone with a hobby or side hustle that involves working with many metals or machinery can.

For example, someone who toys with cars a lot may want a hydraulic press for their garage. It can be a smaller press like the ones used on farms provided you are not working on large trucks or other specialty vehicles.

How Much Money Is a Hydraulic Press?

The cost of a hydraulic press depends on its weight and size. Small lightweight units cost less than one thousand dollars, while larger heavyweight presses cost $2,000 or more.

The smallest hydraulic presses weigh between one and 25 tons (2000 and 50,000 lbs). They’re priced less than a thousand dollars, some as low as a couple hundred. Hydraulic presses this size are best for general repairs at home or in a small shop.

Larger hydraulic presses weigh over a hundred tons (200,000 lbs) and cost thousands of dollars. For example, a 1,500-pound (0.75-ton) hydraulic press costs $6,000 on average. These are large presses used for large shops or people with specialty press needs.

If you search on Amazon, you’ll find hydraulic presses within the above price ranges.

For example, this Shop Press from Amazon.com costs a few hundred dollars and can bend, stamp, and press metal up to six tons (12,000 lbs):

On the other hand, the BIG RED Torin Steel H-Frame Hydraulic Press from Amazon.com with a 12-ton (24,000 lbs) capacity and double the force costs almost double the price of the six-ton (12,000 lbs) press:

Remember that the amounts listed in this section are just general estimates, and the actual cost of a hydraulic press can vary in either direction. Also, be sure to consider what you’ll be using your press for and how much storage space you have so you don’t end up overspending on a unit that doesn’t fit your workshop or garage.

Types of Hydraulic Presses

There are many types of hydraulic presses. However, they can be classified into two categories: fabrication and small business presses, and industrial presses.

Let’s discuss each category in greater detail.

Fabrication and Small Business Types of Hydraulic Presses

Fabrication and small business presses come in many forms:

- The shop press. Shop presses are one of the most popular types of hydraulic presses for hobbyists and small businesses. These are the standard versions of a press that mount to the floor or workbench and can be used in various business and home applications.

- The H frame press. This is a large floor press. Each one has a frame, a press cylinder, a movable bolster, and a pump, which all together make an H shape (hence the name). H frames come in various sizes and are great for repair and maintenance shops or on an assembly line.

- The C-frame press. This is a more portable version of the H frame. These presses have a steel frame and a removable cylinder. They can be mounted onto any surface in your shop, but they don’t have to be. While they’re not as strong as some H frames, they’re ideal for holding parts in place or even removing objects.

- The 4-post press. One of the strongest hydraulic presses, these units have a high maximum force, one or two cylinders, and different beam quantities depending on the intended use. They’re particularly great at pressing symmetrically and precisely, so be sure to buy one of these if your work requires precision and symmetry.

- The benchtop press. This is a smaller version of an H-frame, meant to sit on a bench or table. You can mount them to a specific area or move them easily compared to other larger presses. You should consider a benchtop press if you use your hydraulic press for low-volume projects or need to quickly assemble small parts like bearings.

Industrial Types of Hydraulic Presses

Now let’s look at the types of hydraulic presses used for industrial purposes.

- Laminating press. As the name suggests, these are used to laminate items like sportswear, footwear, countertops, flooring, items used in a laboratory, and electronic devices. They use strict temperature and pressure controls to melt and adhere to materials together. Their heat source is usually steam, oil, or electricity.

- Stamping press. This type is commonly used for electronics, sheet metal, car parts like engines, construction safety items, and aerospace parts. Stamping presses have a wide force and stroke range, which is controlled and contributes to higher cycle turnover rates.

- Transfer press. These are some of the strongest hydraulic presses. They’re made of stainless steel, giving them the ability to press up to 3,500 tons (7M lbs). These presses are either single or multi-line sets of presses, commonly used for medical, military, car, and electronic items.

- Vacuum press. This type is common in factories and manufacturing shops and is characterized by a tight vacuum seal that helps improve the quality of manufactured items. However, the vacuum element causes the press to take a lot longer than the other presses in this section and lowers the pressure.

- Platen press. This is usually used to make rubber, plastics, and parts for air and space machines and vehicles. These presses use a lot of heat and force, making them great for shaping the strongest materials and shapes.

- Forging presses. These are fast and accurate, so they can process a high amount of materials in a short amount of time. They’re usually used for aircraft items, car axles and gears, and other metal objects.

How Are Hydraulic Presses Powered?

Smaller hydraulic presses are often powered manually, while their larger counterparts are powered by electricity. Some presses known as hydraulic power units have built-in power sources, while their air over hydraulics counterparts are powered by pressurized air.

Let’s review the four types of hydraulic press pumps, categorized by how they’re powered.

- Manual powered hydraulic presses have the least amount of force since you have to supply the force with your own hands. These manual presses have hand pumps that allow you to move the pump as fast or as slowly as possible. They’re the cheapest presses, but aren’t a good idea if you use your press often.

- Air over hydraulics presses compress air and oil to create force. Since all you need to provide is the oil in the press, these types of hydraulic presses are often cheaper than other hydraulic presses, and they are more energy efficient. And since they’re simple machines, they have less moving parts, which translates to less maintenance and quieter operation.

- Electric powered presses have a more consistent pump than manual ones, which also means a more consistent force.

- Hydraulic power units have their own power, including a motor, a fluid reservoir, and a pump. The motor’s size determines how much force and pressure the hydraulic pump exerts.

There are also a few types of hydraulic pumps that help create pressure from the hydraulic fluid within the press. You can learn about six of them in this YouTube video from Technical Piping:

Benefits of Hydraulic Presses

Hydraulic presses have a lot of benefits for independent workers and large-scale manufacturers. These benefits apply to all types of hydraulic presses mentioned in this article, so you know you are making a good investment regardless of the kind you end up choosing.

- A hydraulic press is cheaper than other press machines that perform similar functions. Not only do they cost less to purchase, but they cost less to maintain. They’re high-quality machines (especially if you buy from a trusted manufacturer), so they don’t break as often as other presses. And when necessary, you can easily replace any broken parts.

- Hydraulic presses have safety features to help prevent accidents and injuries. The pressure level of your press is the maximum pressure it’ll ever exert. It’ll never be more than you expect, even if you set the pressure level to lower than the maximum.

- Hydraulic presses are quiet compared to other machines. You don’t have to worry about excess noise when using them or have to use any special safety equipment to address loud noises. The quietness is thanks to the smaller quantity of moving parts, which also benefits safety and cost. Fewer parts mean less risk of someone getting injured, less risk of something in the press breaking, and you needing to pay for repairs.

- Hydraulic presses are compact. While they can be considerably large, they’re easy to fit into most factories or other workspaces. Put otherwise, a hydraulic press is an ideal choice if you want to save space without sacrificing any features.

Designing a Hydraulic Press

The first step in designing a hydraulic press is understanding the various parts. A standard hydraulic press has four main parts:

- The frame. This is the main structural piece of the hydraulic press and comes in different shapes like an H frame and a C frame, as described earlier.

- A table or bolster. The table or bolster is where the item you’re pressing sits on. It can be stationary or movable, which is common in H frame presses.

- A cylinder. The hydraulic cylinder(s) make your press work. You need to get cylinders large enough and with the right force to have a functioning hydraulic press.

- A pump. It powers the hydraulic cylinders and gives them the force they need to apply pressure.

When designing a hydraulic press, you should also consider all the different types of hydraulic presses, both fabrication and industrial, and the different power source options. We described the four options of hydraulic pumps earlier in the article, so I won’t go into that.

If you want to see some examples of hydraulic press designs for inspiration, we have some great ones on our website.

The 25 Ton Hydraulic shop press guide has all the information you need to build a shop press, a metal punch, and a metal brake. The plans include more than thirty drawings of individual parts and shop layout drawings, a materials list, and a list of where to buy the materials.

We also have a 50-ton shop press with punch and press brake attachments. The plans come with a material and supply list that contains everything you need to build a heavy-duty H-frame hydraulic press.

Learn More Hydraulic Presses

Hydraulic presses are a great item to have in your workspace, but there are many different types of presses to choose from, and there’s a lot you can learn about what presses can do and how they work. In this section, I’ll provide some great resources you can use to learn more about hydraulic presses and how to design and build them.

First up is a great book from Amazon: Hydraulic Forging Press for the Blacksmith. You’ll learn the history of the hydraulic press, what you can use a hydraulic press for, and how the forging press compares to other types of machines. There’s also information about finding the best press for you and how to get the most out of your hydraulic press.

Here are a few YouTube videos you’ll want to check out that can teach you how to make a small version of a hydraulic press at home. Making these is a great way to learn more about how hydraulic presses work or play around with design options before deciding what type of hydraulic press you will buy or make for yourself.

The Q teaches you how to build a hydraulic press using wood, syringes, pipes, and glass that can press and crack common items like nuts and soda cans:

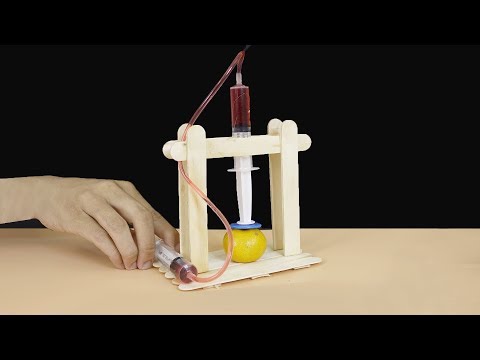

Gimmy TV shows you how to make a smaller, hand-held version of a hydraulic press that has more basic materials like popsicle sticks:

A satisfying video on YouTube from Hydraulic Press Channel shows off some of the strongest items, like bones, car parts, and metal objects, being crushed in a hydraulic press:

Final Thoughts

Hydraulic presses are versatile machines beneficial to independent workers and large manufacturers alike. There are many types of hydraulic presses, each with pros and cons that make it better for industrial over personal use and vice versa.

You can also design your own hydraulic press. While this can be time-consuming, it’s cheaper than buying one; not to mention you can customize your unit’s specifications to your needs.

Hopefully, you’ve understood how hydraulic presses work, what options you have when buying one for a specific job, and how much you can expect to pay.

Sources

- Britannica: Joseph Bramah

- Agriculture: Hydraulic Presses

- Grainger: Types of Hydraulic Presses and How They Work

- Hydraulic PressManufacturers: Laminating Presses Suppliers, Stamping Presses Suppliers, Transfer Press Suppliers, Vacuum Presses Suppliers, Platen Presses Suppliers, & Forging Presses Suppliers

- Safety Lifting Gear: The Hydraulic Press

- Bernell Hydraulics: History Hydraulics

- IQS Directory: Hydraulic Press

Amazon Affiliates Disclaimer.

This site is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. We are compensated for referring traffic and business to Amazon and other companies linked to on this site. Some of our links are affiliate links. We make a small commission if you use these links. As an Amazon Associate, I earn from qualifying purchases. It is important to do your own research to find what works best for you.